Why Lot Numbers and Serial Codes Matter More Than Ever

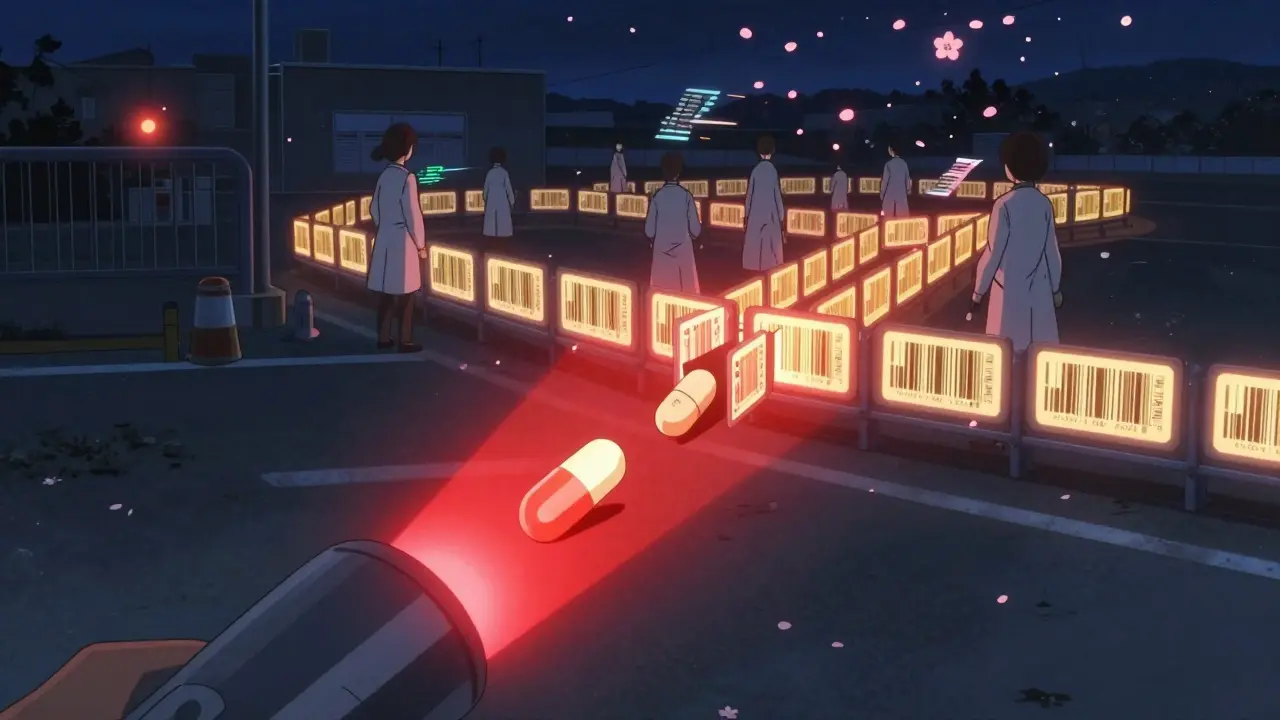

Every pill, vial, or box of medicine you buy has a hidden story. It’s written in a string of letters and numbers-lot number or serial code-that tells you exactly where it came from, when it was made, and who handled it along the way. In the fight against counterfeit drugs, this isn’t just paperwork. It’s a lifeline.

Counterfeit medications are a global crisis. The World Health Organization estimates that 1 in 10 medical products in low- and middle-income countries are fake. Even in the U.S., the FDA seizes thousands of illegal drugs every year-some laced with fentanyl, others containing no active ingredient at all. Without lot numbers and serial codes, there’s no way to know if your medicine is real or dangerous.

What’s the Difference Between Lot Numbers and Serial Codes?

Lot numbers and serial codes sound similar, but they do very different jobs.

A lot number identifies a group of products made together under the same conditions-same batch, same machine, same day. Think of it like a family: all the pills in that lot were born from the same production run. If something goes wrong-say, a contaminated ingredient-the entire lot can be pulled without touching other batches. This cuts recall costs by up to 63%, according to FDA case studies.

A serial code, on the other hand, is like a fingerprint for a single unit. Every bottle, every blister pack, every syringe gets its own unique number. This level of detail is critical for high-risk items like injectables, cancer drugs, or medical devices. If a counterfeit vial shows up in a hospital, serial tracking can trace it back to the exact warehouse, distributor, or pharmacy that sold it.

Pharmaceutical companies use both. Lot numbers handle broad safety sweeps. Serial codes hunt down individual bad actors.

How Track-and-Trace Systems Work in Real Life

It’s not magic-it’s barcode scanning and software.

At the factory, each lot gets a printed label with a QR code. As the medicine moves through warehouses, trucks, and pharmacies, workers scan it with handheld devices. Every scan logs the time, location, and person who handled it. That data goes into a secure cloud system, creating a digital trail from the raw chemical to your medicine cabinet.

When a problem arises-say, a batch of blood pressure pills was exposed to heat during shipping-the system can instantly pull up every single unit from that lot. No guesswork. No fishing through boxes. In minutes, pharmacies know which shelves to clear. Patients get notified. The bad batch never reaches most people.

One major U.S. pharmacy chain reduced its recall response time from 72 hours to under 20 minutes after switching to serial tracking. That’s not efficiency-it’s safety.

Why This System Stops Counterfeiters

Counterfeiters don’t want to be tracked. They rely on chaos. Fake drugs often come in poorly printed boxes with smudged lot numbers-or no numbers at all.

Legitimate pharmaceuticals use tamper-proof labels, encrypted codes, and blockchain-backed logs that can’t be altered. If a bottle’s serial code doesn’t match the manufacturer’s database, the system flags it immediately. Pharmacies and regulators get real-time alerts.

In 2023, the FDA blocked over 1.2 million counterfeit opioid pills at U.S. borders. Most were caught because their serial codes didn’t exist in the official registry. That’s the power of traceability.

Even small pharmacies are now required to verify serial codes before dispensing certain high-risk drugs. If they can’t scan and validate it, they can’t sell it.

Regulations That Made This Mandatory

This isn’t optional. It’s the law.

The Drug Supply Chain Security Act (DSCSA), fully enforced by 2023, requires every prescription drug in the U.S. to have a unique serial number and be traceable through the supply chain. By 2025, all transactions must be digitally verified.

Outside the U.S., the EU’s Falsified Medicines Directive has similar rules. India, Brazil, and China have rolled out national serialization systems too. The goal? No fake drug can slip through without leaving a digital trace.

Companies that ignored these rules are getting hit with fines, shutdowns, and criminal charges. In 2024, a distributor in Florida was sentenced to 10 years in prison for selling untraceable insulin that caused three patient deaths.

What Happens When Tracking Fails

It’s not just about fraud. Poor tracking kills.

In 2022, a hospital in Texas received a batch of chemotherapy drugs with a mismatched lot number. The system didn’t catch it because staff entered the number manually instead of scanning it. The drugs were later found to be contaminated with a toxic chemical. Six patients suffered severe reactions.

The root cause? No barcode scanners. No training. Just handwritten logs.

Studies show that manual data entry leads to errors in 13% of cases. Scanning drops that to under 0.5%. Yet, many small clinics and rural pharmacies still rely on paper. That’s a gap counterfeiters exploit.

What You Can Do as a Patient

You don’t need to be a tech expert to use this system.

When you pick up a prescription, check the label. Does it have a barcode or QR code? Ask the pharmacist: “Can you scan this to confirm it’s legitimate?” Most will do it right away.

If you buy medicine online-especially from websites offering “discounts” or “no prescription needed”-be suspicious. Legitimate pharmacies don’t sell drugs without traceable serial codes.

Report anything that looks off. The FDA has a portal for reporting counterfeit drugs. A single report can stop a whole shipment.

The Future: AI, IoT, and Real-Time Alerts

Track-and-trace isn’t standing still.

By 2027, most systems will use AI to predict risks. If a shipment of insulin shows unusual temperature spikes during transit, the system won’t just log it-it’ll flag it before it even reaches the pharmacy.

Some companies are testing IoT sensors inside packaging that send live data on temperature, humidity, and shock. If your medicine got dropped or left in a hot truck, you’ll know before you take it.

Blockchain is being used to make logs tamper-proof. Once a serial code is recorded, it can’t be changed. That’s a game-changer for global supply chains.

Bottom Line: Trust, But Verify

Lot numbers and serial codes are the invisible shield between you and dangerous fake drugs. They’re not perfect-but they’re the best tool we have.

For manufacturers, they mean compliance and safety. For pharmacies, they mean liability protection. For you, they mean peace of mind.

If you ever wonder whether your medicine is real, remember: it’s not about the brand. It’s about the code. And that code should always scan.

Comments

Yanaton Whittaker

This is why America needs to own the supply chain, not some foreign lab with sketchy paperwork. 🇺🇸 If you can't scan it, don't take it. Period. 🚫💊

Kathleen Riley

The ontological implications of serialization as a mechanism of pharmaceutical epistemology are profound. One might argue that the barcode functions not merely as a logistical instrument, but as a semiotic anchor in the phenomenological experience of medical trust.

Sazzy De

Honestly i just scan the qr code when i pick up my meds now. if it works i dont think about it anymore. peace of mind is kinda nice

Gaurav Meena

In India we’ve been pushing this for years. Small clinics still struggle with scanners but the system works. If we can do it with limited resources, imagine what full adoption can do. Keep pushing, brothers and sisters 🙏

Jodi Olson

The idea that a string of alphanumeric characters can serve as a moral guarantee against death is both beautiful and terrifying. We’ve outsourced our safety to a database

Amy Insalaco

One must interrogate the epistemological hegemony of serialization as a neoliberal biopolitical apparatus. The DSCSA isn’t about patient safety-it’s about commodifying traceability as a regulatory fetish, reinforcing supply chain capital through algorithmic occlusion. The QR code is the new panopticon, and we’re all voluntarily scanning ourselves into compliance.

Natasha Plebani

Blockchain integration is the logical next step, but it introduces a new vector of failure: cryptographic centralization. If the root CA goes down or is compromised, the entire chain of trust collapses. We're building a cathedral on sand, and calling it immutable.

Eliana Botelho

Okay but what if the scanner breaks? Or the wifi is down? Or the pharmacist is just lazy? I’ve seen them type in codes by hand even at big chain pharmacies. This whole system is built on the assumption that humans are robots. They’re not. And people die because of that. I’ve been there. Don’t pretend this is flawless.

Rob Webber

This is why we need to stop letting China and India make our pills. You think your insulin is safe? It’s probably made in a basement with a printer and a prayer. The government’s lying to you. This traceability crap is just a distraction while they let foreign labs poison us.

Lisa McCluskey

I work in a rural pharmacy. We got scanners last year. Took 3 months to train everyone. Now we catch 1-2 fake meds a month. It’s not perfect but it saves lives. Don’t underestimate the power of a simple scan

owori patrick

In Nigeria we dont have all the tech but we use community trust. If a drug feels off, we ask elders. If the label looks wrong, we dont sell. Tech helps but people still matter. We need both

Claire Wiltshire

It's worth noting that the integration of serialized tracking systems has significantly reduced medication errors and adverse drug events. The data is clear: standardized, machine-readable identifiers correlate directly with improved patient outcomes. This isn't just regulation-it's clinical best practice.

Mike Rose

all this tech is cool but i just check if the bottle looks right. if it dont look like the last time i got it i dont take it. why make it so hard?

Sidhanth SY

I’ve seen this work in a village clinic in Bihar. No internet, but they used offline scanners synced weekly. One fake insulin was caught because the serial didn’t match the registry. Tech doesn’t need to be fancy to save lives.

Eliana Botelho

Exactly. My aunt’s clinic in Ohio still uses paper logs. They got a shipment last year with a fake lot number. No one caught it until the patient started vomiting. Scanners aren’t magic. Training is. And nobody trains anyone anymore.